Increase your production quality!

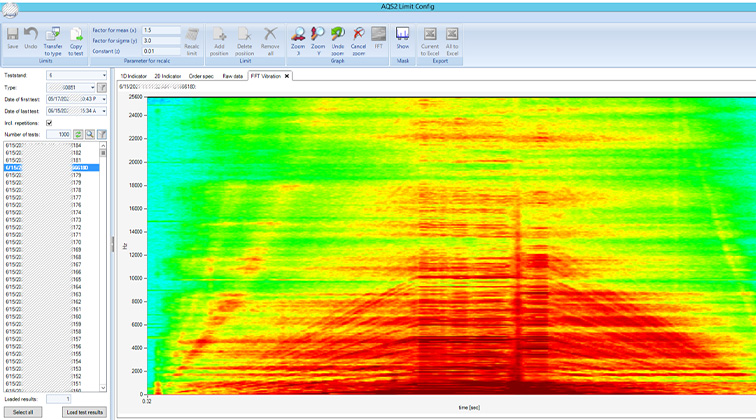

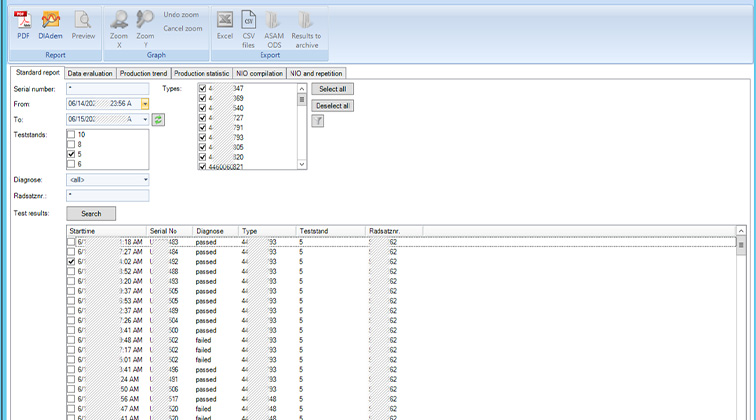

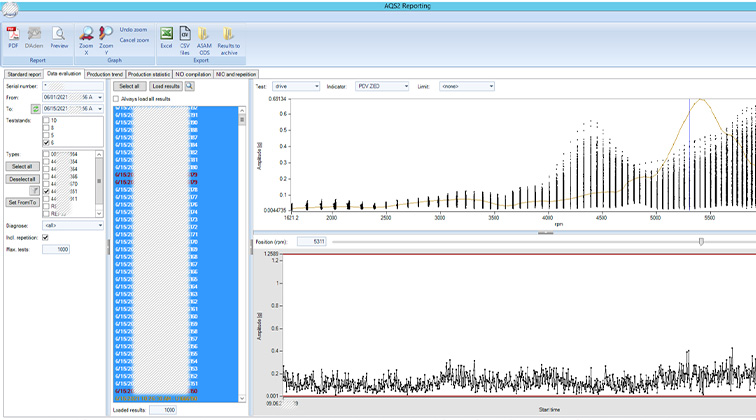

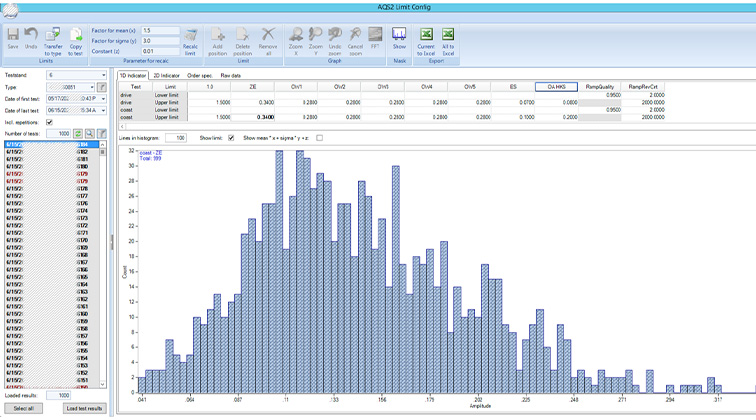

With the MIG16 AQS we have created an optimal noise measurement system for the end-of-line test bench. It reliably detects assembly errors and identifies missing or damaged parts, monitors the noise level of the test item and provides information about gear, pump and turbine noises as well as knocking, squeaking, scraping or rattling noises.

Whether for transmissions, axles, electric motors and combustion engines, seat adjusters, hoods or shock absorbers - our measurement technology is successfully used in the final testing of a wide variety of components. Our customers particularly appreciate the cost-effectiveness and extreme reliability of our individually tailored system solutions.